What Is Lithographic Printing: Its Process And Benefits.

Lithographic printing is the oldest printing method that mankind has used till date. Lithography printing was once done on limestone but now many new and different types of materials are used.

So what makes this old printing technique so relevant that even now in this digital age, we are still using this printing method?

What exactly this process is and what are the benefits of this process that make it a preferred choice for other printing presses and businesses?

If you want to know the answers behind this, this blog is for you.

In this blog, we are going to talk about the process of lithographic printing and then we will talk about the benefits that we get from this printing.

What Is The Lithographic Printing Process?

The word lithography is made from two words, the first ‘Litho’ and the second being ‘Graphy’, where Litho means stone and Graphy means printing.

The name originated from its way or method of printing. This printing method was invented by Alois Senefelder in 1799.

The principle behind this printing process is that water and grease do not mix and this was used to make ink dispensing and printing a more straightforward process.

In the older days, this was done with limestone and using different chemicals. But now a variety of material is used.

Let’s dive into the process of lithography or offset lithography that is used in present-day printing press.

Here, we are going to talk about this process in the following steps.

1. Making Press Plate

The first and most crucial step starts with making the impression plate that will be responsible for printing the impressions on the paper.

For this a sheet of aluminium is used to make the impressions, This is done with the help of a laser which infuses the surface with images or text whatever is required to get printed.

This aluminium sheet is known as Press Plate.

Installing the press plate in the machine

Now the next step is to install the press plate into the printing press machine. Now for each colour, we need to have a separate press plate. Usually, the colours that are used in Lithography printing are CMYK which consists of Cyan, Magenta, Yellow and Key which is black colour.

To get a high-quality image or text, we need a mix of all these colours, some of the lower-quality prints tend to miss one of these colours.

Now that the ink fountain has been filled with the required colours, it's time to start the print.

2. Damping Units With Water

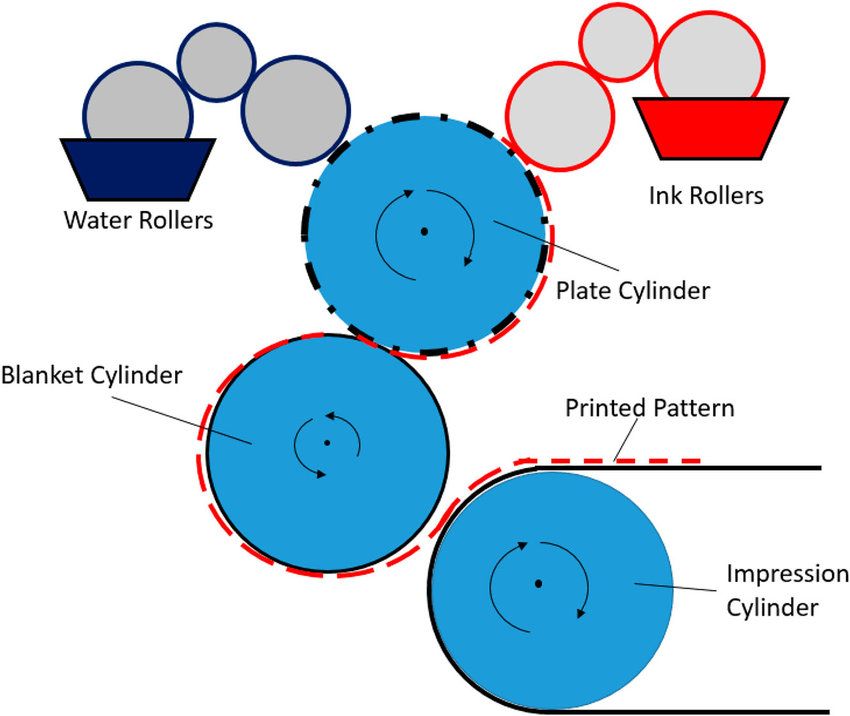

The process starts with damping the cylinder with a solution of water and chemicals. This solution is used to dampen the rolling cylinder after which the press plate gets stuck with it.

3. Ink Fountain

From the ink reservoir, the ink starts pouring into a cylinder that transfers the paint into another cylinder that gets the imprint of the ink.

4. Press Plate Image

Now a sheet of paper is moved between the two cylinders which are the impression cylinder and the blanket cylinder. These absorb the solution of water and chemicals.

5. Blanket Cylinder

In this area, the impression cylinder that absorbs the ink is pressed to remove extra ink and water.

6. Impression Cylinder

Now that excess ink is squeezed out and the sheet of paper is rolled between this impression cylinder and the blanket. This gets the paper printed but this is still damp so it is important to pick it carefully and dry it.

7. Transfer Drum

This is the last step in Lithography Printing, where the damp paper is dried and transferred into a transfer drum.

And we get a printed media.

It might look like a long process but this whole process of printing is done within a second.

What Are The Benefits Of Lithographic Printing?

Now that we know the process of lithography printing method. In this section, we will talk about the benefits and reasons that are behind the success of a 200-year-old printing technique.

This is possible only because of the constant improvement in this process. Keeping that in mind, we will talk about those benefits in

High Volume

As this printing method was made for commercial purposes, this is perfect when we need hundreds or maybe thousands then this is ideal for you.

As commercial printing, we need to get identical prints without any changes then you should opt for this one.

Minute Details

The reason lithographic printing is highly sought after is because of high-quality prints and the ability to print even minute details. The reason for this is because of the colour scheme used, we are talking about CMYK.

This combination of colours is said to produce the highest quality of printed media. Not only this but this printing can be done on several different finishes like matte, glossy, semi-glossy, etc.

Cost-Effective

Lithographic printing is not only great at printing high-quality prints but also cost-effective. As in commercial printing, we have to print in large quantities.

The cost of lithography printing goes down with this, as the cost of offset or press plate is covered.

Quick And Efficient

Despite having a complex and multi-step process used for modern lithography printing, the overall time to actually get printed is very short.

It is a speedy and efficient way to get your required amount of printing media in a limited time. This makes it perfect for printing all kinds of eCommerce Packaging.

Conclusion

We had a deep discussion regarding the Lithographic printing. We began our discussion by explaining what is lithographic printing. The fact that it is the oldest printing technique that is still in use and is giving cut-throat competition.

The reason behind this is the constant improvement and innovation in this printing method. Despite a lot of changes done to Lithographic printing, the main principle is the same.

That Grease and water do not mix and we can use it to imprint the symbols on a different surface.

After this, we had an in-depth discussion about the process. Then we headed to talk about reasons which make this printing method highly effective in this digital and competitive world.

And this is all we have to say about lithography printing.

Suman Mandal has been in the packaging industry for a long time. She is passionate about the innovative ways this industry comes up with. Currently, she is writing for To The Packaging about various packaging solutions.