Water Activated Tape vs. Pressure Sensitive Tape: Which is the Right Choice for Your Packaging Needs?

Clear, brown, kraft, tissue, foam tape, duct tape, thick, synthetic resin, and whatnot. The list goes on and on, thou it is good to have options and choices. But sometimes it is best that so many options but it gets confusing at some points.

When we are looking for something and we are bombarded with too many options, it gets confusing to pick even simple things like tape.

Tape is something that a normal person would not think twice while buying but a person who is from the packaging industry would not think so.

As Tape plays an integral role in the packaging industry. It is a handy and easy-to-use tool that has helped us with simple to complex tasks.

As it is so important to pick the right kind of tape according to your needs. There are several types with different properties and advantages. But how do you know which ones are right for you?

To clear out the doubts that people have about the tape. We have decided to clear out some of the doubts about these types.

In this blog, we will talk about water-activated tape and pressure sensitive tape. We will begin by explaining what these two tapes are and what is their purpose and then we will see which one is good and the right choice for you.

If that is something that sounds interesting to you.

Then stay with us til the end!

What is pressure sensitive packing tape?

Pressure sensitive packaging tape refers to the type of tape that will adhere or stick to the surface on its own just by applying little pressure on it. It does not require any other medium like water or heat for binding to other surfaces.

Pressure sensitive tapes are the type which is widely popular and available everywhere.

What is a gummy tape?

Gummy tape or water activated tape needs water to bond to the surface. the adhesive is made from starch and the backing material is usually biodegradable.

As the adhesive is activated only by water it is called water-sensitive tape.

What is the purpose of water activated tape?

In the above section, we have learned about what a water activated tape is. Now we will read about the purpose of water activated tape. Where we will talk about the reasons why use should choose water activated tape.

The water-activated tape was invented by Thomas Edison in 1912. It made its comeback in modern times due to the need for tamper-proof packaging solutions.

Here, we will discuss a few things that make this tape special.

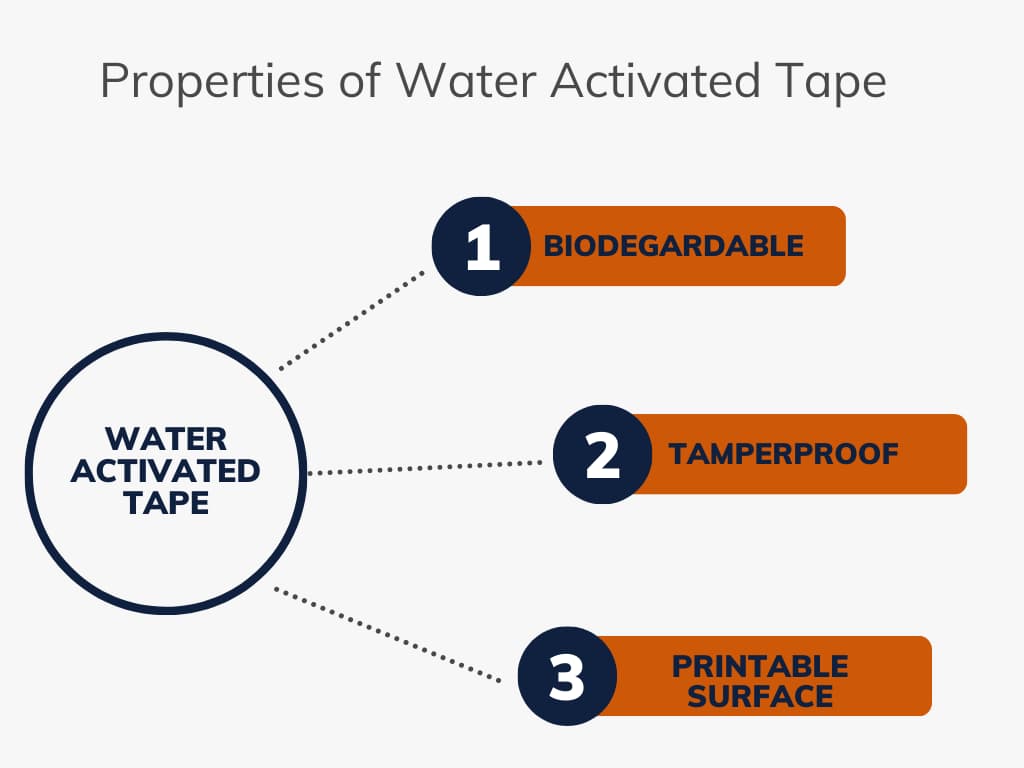

Biodegradable

Water-activated tape or gummy tape is made from plant starch and the backing material is made from different types of fibre or kraft material.

Due to the tape being made from biodegradable material, it is environmental-friendly.

Tamper proof

When a water activated tape is stuck to the surface, it bonds quickly and strongly. In such a way that many times when you try to take off the tape, it comes off with a layer of corrugated box which makes it tamper evident.

Easy to print

Most of the water activated tapes have an easy-to-print surface which is a plus point. As a single product can be used to make marketing and advertising.

What are the advantages of pressure-sensitive adhesive tape?

This is a tape that is being used widely for a long time. As we have talked about what a pressure sensitive tape is. Now is the time to talk about the advantage that we get from using pressure-sensitive tape.

Most of the qualities that we are going to talk about are a mixture of many different kinds of pressure sensitive packaging tapes which are available in the market.

If you are looking for a single type of tape that possesses all the qualities that we have mentioned below then you should go for high-quality BOPP tapes. If you are new to this tape, you can check this link out for more information.

Cost-effective

As pressure sensitive tape is very popular, it is produced in mass quality it is relatively cheaper than other types of tapes.

Most of the raw material and the making charges are low which makes it an affordable choice among people.

Moisture resistant

Most of the pressure sensitive packaging tapes show good resistance to moisture to a certain extent which is not found in the water activated ones.

Easily printability

Just like water-activated tapes, pressure-sensitive tapes also have a high-quality surface which is seen to have good printability and shows no bleeding or fading of colours.

Recyclable

As we have said there are many types of materials used to make pressure sensitive packaging tapes. Many of these tapes are made in such a way that they are recyclable as well as environment-friendly.

UV resistant

When we are talking about UV resistance, we are talking about the colour, clarity, and adhesiveness that are said to get dull with long exposure to sunlight.

What tape should I use for packaging?

Now that we have talked about both water activated tape and pressure sensitive tape. It is time for the moment of truth that is which tape is better and which one is not.

As we have seen the properties that are offered by the water activated tape is similar to pressure sensitive tape. There are a few differences which are water being used as a substrate to activate the adhesive of this tape while pressure-sensitive tape does not need anything like that.

As water-sensitive tape’s usage is a bit different, it cannot be used with normal handheld tape machines. We need to change them.

But if you are looking for something that is strong and will prevent tampering. You should go into this option.

The water-activated tape gives good adhesive properties but it is not cost-efficient. Pressure-sensitive tapes cost less than these tapes.

If you look hard enough you will be easily able to find a pressure-sensitive tape that has strong adhesion and all the other properties that a water-activated tape has.

That’s all we have to say for now.

Thank you for reading!

Suman Mandal has been in the packaging industry for a long time. She is passionate about the innovative ways this industry comes up with. Currently, she is writing for To The Packaging about various packaging solutions.