How To Select the Right Corrugated Box For Different Industries?

When we order products online, most of the time we receive a corrugated box which more than often, is ignored. But do you know the journey of the product in your hand is incomplete without the corrugated box?

A corrugated box played a vast and important role to keep your products safe and sound if you are a business owner or someone who will be starting a business soon.

For them, it is important to know, what kind of packaging and box they need to make sure that their product reaches the customer safely.

If you realise how important it is for a business to have secure packaging, and want to know how and which type of packaging is something that you should choose for your business and products.

Then we have something for you as you must have read the title of this blog. We will be talking about the ways and things that one should know to select the right corrugated box for different industries.

If that is something you are looking for then stay with us.

How Many Types Of Corrugated Boxes Are There?

We know that different types of packaging solutions are available in the market but here we are going to talk about the most widely used and popular packaging solution.

Not just the most popular it is one of the first packaging solutions that has existed.

We are talking about corrugated boxes. Given it is the oldest packaging solution, it is available in various sizes, shapes, colours etc.

In this section, we will talk about different types of ply of corrugated boxes.

Types Of Ply

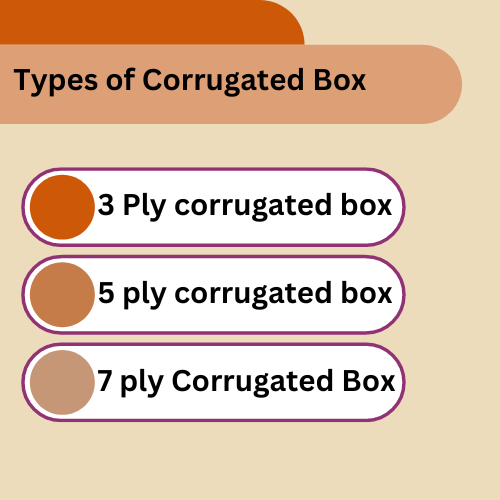

Before talking about the types of ply, we will talk about what is a ply in a corrugated board.

Ply is a board that consists of a minimum of 3 and a maximum of 7 layers of cardboard lining.

Given this information, there are 3 types of ply, which are available in the market which are 3ply, 5 ply and 7 ply respectively.

What Is A 3 Ply Corrugated Box?

A 3 ply corrugated box is made from 3 ply cardboard which consists of 2 different types of cardboard liners. One is a flat cardboard liner and the second is a flute.

We know what a flat cardboard liner is and how it looks like

A flute is a wavy cardboard that is sandwiched between two flat liners.

When we have a layer of flat cardboard liner, then a layer of flute and then again a flat cardboard liner as it has three layers it is called 3 ply cardboard.

A 3 ply box is widely used in the eCommerce business for delivery as it is strong and lightweight but can not support too much heavy weight.

What Is A 5 Ply Corrugated Box?

A 5 ply corrugated box is made from a 5 ply board which consists of two flute liners or profile and three flat liner stacks in order of flat liner over flute and then again a flat liner till it reached 5 layers.

A 5 ply box is considered a heavy-duty box that can hold up to 12 kg of weight depending upon the size of the box.

What Is 7 Ply Corrugated Box?

Just like 3 and 5 ply, a 7 ply corrugated box consists of 7 layers with 3 layers of flute profile and 4 layers of the plain board.

It is the most durable and strong box as compared to the 3ply and 5ply boxes. You can use a 7 ply box to send or deliver things like nuts, bolts or other kinds of heavy objects, or it is also used to deliver delicate and fragile products like electrical appliances.

If you want to know more about different types of corrugated boxes on the bases of ply. You can check out this blog.

How Do I Choose A Corrugated Box?

After reading the last section, we got to learn about the different types of corrugated boxes on the bases of different types of ply.

Now we will discuss different aspects of a corrugated box that will show which one is the best choice for you and your requirements.

In this list, we are going to talk about the different types of tests that are performed on a corrugated box to know how will it perform and the level of protection it can provide.

Down below, we have a list of tests that are done on boxes to know about their strength and capacity to handle force and stress.

Product Classification

Product classification is not any kind of test but more like a requirement that a person has to do on their own.

Product classification simply refers to seeing what kind of products you have and what your needs are. For example, a cosmetic product will have different requirements than a box of nails, bolts, and screws.

So before anything else, make sure that you know what you need and looking for.

Bursting Strength

What is bursting strength? Bursting strength is the amount of stress or pressure that it takes to tear it apart. It is essential to know how much stress it can handle so that we know what kind of products can we put inside it.

The formula for calculating bursting strength is

Burst Index = Burst strength/Grammage

Where burst strength is in gf/cm2 (gf = gram per force)

And grammage is the base weight in gf/m2

Edge Crush Test

As the name suggests, this test is required to know how much strength is required to crush or deform a box. This test is done to see if the box is strong enough to hold the weight of products and protect them if they fall during transit.

This test is performed when vertical force is applied to the box so that we know how much strength is required to crush the box and the content according to it.

Grade Of Paper

The quality of the paper or material used to make a corrugated box also plays an essential role in deciding the strength factor. Though the requirement of the customer may vary. The need to have safe deliveries is persistent.

Many kinds of paper are available in the market if we want to make a list of all the names, then we will come across more than 6000 types of paper and more.

Paper is classified into 6 categories which are:

- Based on GMS

- Based on the finish

- Based on colour

- Based on raw material

- Based on coating

- Based on texture

All these factors are responsible for the different types of paper. It would not be possible to explain all that if you want to know more about it. Click on this.

How Do I Choose The Right Box?

Now that, we have discussed all the things that are required to choose the right box, you might have got an idea of the parameters that you should keep in mind while looking for the right box.

The right box is different for every person as different person has different requirements. So the right thing would be to do some research and know what is right for you.

That's all for now, thank you for reading til the end.

Suman Mandal has been in the packaging industry for a long time. She is passionate about the innovative ways this industry comes up with. Currently, she is writing for To The Packaging about various packaging solutions.