Difference Between Flexographic Printing And Offset Printing

Flexographic printing and offset printing are the most popular types of printing that are dominating the printing industry. You will be surprised to know that these two printing techniques are most popular in the printing and packaging industry.

But what exactly they are, their process of printing and the difference between them?

If you are curious about all these aspects of packaging then this blog is for you, as we are going to talk about all these things and more

So without wasting any more time let’s dive into this.

What Is The Flexo Printing Process?

The flexographic printing process is a fast-paced printing process in which the impression plate also called the press plate is flexible.

In older times, the press plates were made of rubber but now a flexible photopolymer is used. It is a popular method for printing long-form printed media like labels, Custom Printed Tape, Flexible product packaging and many more things.

How Does Flexography Work Step By Step?

Now, that we know what is flexographic printing, we are going to talk about the process of flexography work step by step.

In this section, you will find a detailed description of the process through which flexographic printing is done.

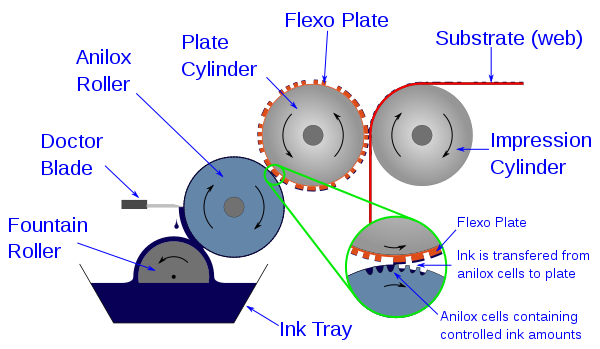

So the process starts with making a press plate. But what is a press plate? A press plate is a sheet which has the impression of the image and the words that you have to print.

- To make a flexible press plate one has to get designs printed on the Photoploymer sheet.

- To make impressions of the design, we have to expose it to UV rays so that this photopolymer sheet gets raised impressions.

- Now that we have got our flexo press plate, we will install it on a cylinder called a plate cylinder.

- The plate cylinder is one of the four major cylinders that handle the whole printing press. The names of the rest of the cylinders are fountain roller, anilox roller and impression cylinder.

- Now that the flex press plate is installed on the plate cylinder. We can move to the other step which is filling ink in the ink tray.

- The popular colour scheme that is used in this printing press is CMYK which consists of Cyan, Magenta, Yellow and key which is black.

- The fountain roller which is present in the ink tray begins to rotate. This fountain roller is in direct contact with an anilox roller.

- As the ink is transferred from the fountain roller to the anilox roller. The amount of ink transfer is controlled by a tool called doctor blade.

- The anilox roller is in direct contact with the plate cylinder, This plate cylinder is the one where we installed the flexo press plate.

- A controlled amount of ink is being transferred on the flexo plate which will come in contact with substrate or printable media.

- The impression cylinder puts enough pressure to make sure that it is being printed.

- And we are done with printing.

Why Is Offset Printing Called Offset?

The word offset means plate, in this case, a press plate. The reason behind it being called Offset printing is that we need to make or change a plate before we start printing or if we want to change something.

Many also call it Offset Lithography printing. If you want to know more about it you can see this blog here.

What Are The Steps Of The Offset Printing Process?

Till now, we have talked about what offset printing is. In this section, we will discuss the process behind offset printing.

We will explain this in bite-size steps so that it is easy to understand. The steps of the offset printing process are as follows:

- The process starts with making a press plate which will have impressions of the image and text that we need. All the things will be made on the aluminium sheet with the help of a laser.

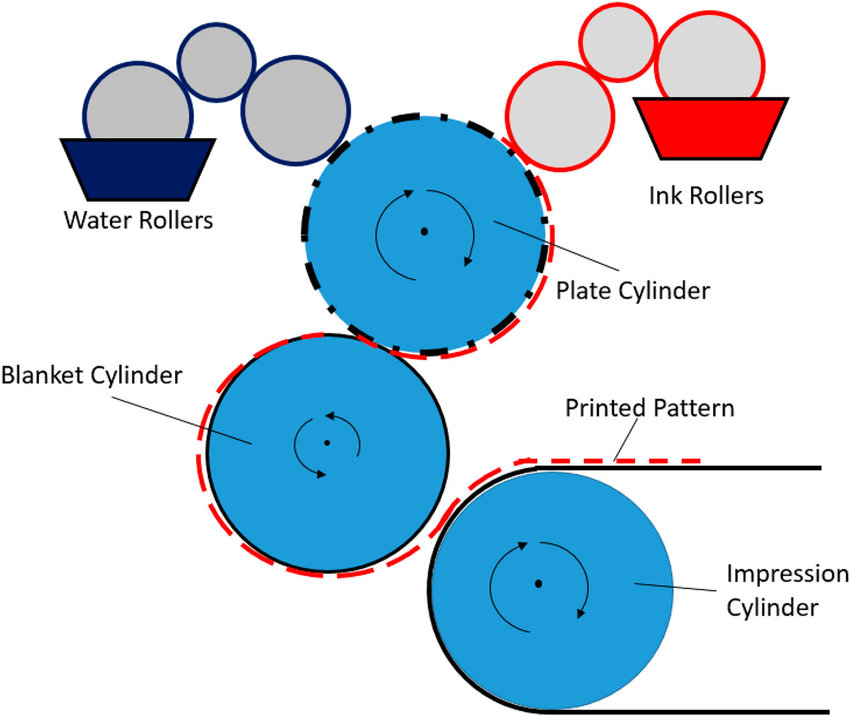

- After the press plate is made, it will be installed in the press machine on the plate cylinder.

- Now we will pour ink in the ink fountain. In the second container, we will have water and other chemicals.

- The colours that are used in this printing method are CMYK which is the same as we used in the flexographic printing.

- Before inks are deposited on the rollers, a solution of water and chemicals is distributed on the plate cylinder to make sure that ink gets on the desired surface only.

- The plate cylinder is in contact with the blanket cylinder. As the plate cylinder is saturated with ink.

- The blanket cylinder gets the ink deposited on it, and then it comes in contact with the substrate which is on the belt of the impression cylinder.

- As the paper is carried out to the blanket cylinder, it is made sure that it is dampened with water and chemicals.

- Then the ink on the blanket cylinder is transferred to the paper or other absorbent type of print media.

- After the paper is printed, it is carried out to the transfer drum to dry and hence our printing process is done.

Even though the process, looks long and sounds complex, all of these steps are done within a few seconds. This is the reason why both offset printing and flexography printing are high-volume and high-speed printing processes.s

This printing process is perfect for Corrugated Boxes which need printing or customisation. Not just this but for other types of printing as well, it is a great option.

What Is The Difference Between Offset And Flexographic Printing?

Now that we have discussed what offset and flexographic printing are as well as their process. For easy understanding, we have made a table which states the different points of offset and Flexographic printing.

| OFFER PRINTING | FLEXOGRAPHIC PRINTING |

|---|---|

| Invented in 1875 | Invented in 1890 |

| Offset means plate. In this printing method, we have a printing plate which is like a solid one. | In Flexographic printing, we have a flexible press plate. |

| Press Plate made of Aluminium | The press plate is made of Photo Polymer Plate. |

| Great for printing packaging materials, books, cards and brochures. | Popular for printing labels and the long form of print media. |

| A total of 2 types of offset printing are available. | A total of 3 types of printing presses are available. |

| Must have a solid flat surface for printing. | Can easily print on any flexible surface. No need for a solid flat surface. |

Conclusion

This was a detailed blog on the most popular printing processes that are dominating the printing industry. We talked about Flexographic printing and offset printing.

In the beginning, we talked about what these press printing processes are then we proceeded to talk about the process in a step by step format.

In the end, we stated the key differences in a tabular form.

That’s all the information that you will get on this topic. We have tried to cover all of the important points in this blog.

Thank you for reading till the end.

Suman Mandal has been in the packaging industry for a long time. She is passionate about the innovative ways this industry comes up with. Currently, she is writing for To The Packaging about various packaging solutions.