BOPP Tape and its manufacturing process

BOPP tape is among the most popular and widely used item in the packing industry. Since the time, it was first introduced in this industry till now. It has become a staple tool for packing different types of corrugated boxes.

But what exactly this tape is? How is it made? What are the raw materials used? Why is it so popular?

In this article, we will talk about all the things regarding BOPP tape. Starting from what is it and what raw materials are used to make it. Then we will talk about its manufacturing process and end the blog with the reasons why is it so popular.

What is BOPP tape?

BOPP tape full form is Biaxially Oriented Polypropylene. This tape has a film of thermoplastic which can withstand a wide range of temperatures. Due to this, it is widely used in the packaging industry.

What is the raw material used in BOPP tape?

BOPP tape is made from a thin film of thermoplastic Polypropylene Polymer. This polymer film can be stretched in both horizontal as well as vertical directions.

Two types of adhesives are used for BOPP tape. One is Hot Melt and another is an acrylic adhesive.

Hot melt adhesive tape is best for packing things that need something strong to hold them while acrylic tape offers a good range of temperature resistance as well as moisture resistance.

We will read more about the benefits of BOPP tape at the end of this article.

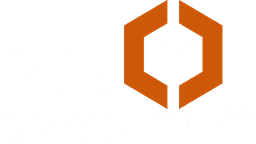

How are Bopp tapes manufactured?

In this section, we will talk about how BOPP tapes are manufactured. We have tried to divide the manufacturing process into different parts so that it is easier to understand.

- As we know that BOPP tape is made from polypropylene material. Manufacturing starts with huge industrial-size rolls of Polypropylene.

- The huge roll is transferred to a machine called Unwinder. As the name explains this machine unwinds the huge roll of polypropylene into another machine.

- During this process, the machine mustn't stop which will hinder the whole process of tape-making. So instead of stopping the machine to change the roll of polypropylene.

- The starting point of a fresh roll is joined with the end of the roll which is on the machine being unwinded. This is done by using adhesive splicing tape. (Splicing tape is used to help in manufacturing by joining the ends of a material with a fresh new roll.)

- Then a machine makes sure that the film is optimally stretched to avoid ripping off the BOPP film.

- A solvent is added to both sides of the film to make sure that it does not stick with the machine roller.

- Then comes the adhesive that will go on one side of the backing material of the tape. Before the adhesive is applied on a tape, it is heated to approximately 200 degrees Celsius. So that it becomes easy to spread the adhesive on the BOPP film. This is done with the help of a machine named Blower.

- The blower is a pre-heated cylinder in which adhesive is heated to apply to the tape. Then the roll of stretched film is attached to a computer sensor which makes sure that the blower spread an equal amount of adhesive on the film.

- When the heated adhesive is applied to the tape, the film is passed on a cooling cylinder so that the adhesive hardens properly.

- Then this adhesive-coated roll goes on a machine named Rewinder which separates the joins that we had taped together in the second step.

- After it is unwinded, this separated roll is transferred onto other machines to cut and divide them according to the customer's requirement.

- Then the divided adhesive rolls will be rolled over cardboard cores.

And here we are left with a freshly manufactured tape.

What are the advantages of BOPP tape?

Till now we have talked about what BOPP tape is as well as how it is manufactured. Now, we will talk about the advantage that BOPP tape gives to its users.

We have listed a few advantages in the following list:

1. Age resistance

Ageing in the tape is referred to as colour fading, loss of gloss, loss of adhesive and yellowness due to constant exposure to atmospheric elements. This leads to the deterioration of the tape.

This is not the case with BOPP tape as the adhesive has many chemical solvents that will prevent it from happening.

2. Water-proof

When the ordinary tape comes in contact with water they tend to lose their adhesive properties. But BOPP tape is totally water resistant. Hence, it is preferred by packaging companies as they look for cost-efficient ways to make keep their packages safe.

3. UV resistance

When an ordinary tape is exposed to sunlight for a prolonged amount of time. Then it begins to lose its adhesive properties, clarity, glossiness, colour, and many more things.

BOPP tape is unbothered by sunlight as its adhesive has a UV-protectant chemical solvent which makes sure that the page does not lose its properties when it comes in contact with heat.

4. Eco-friendly

When we talk about the Eco-friendly side of this BOPP packing tape then we won’t be disappointed with BOPP tape. As it can be easily recycled. You don’t even it to separate the tape from the boxes as they are separated by the recycling plants themselves.

5. Easy to print

We know the importance of custom tape with a logo in building customer loyalty, building brand awareness, marketing and many other things that a good custom tape will take care of.

For a business, it is extremely important to have a good tape that can be customised as they want, this is possible with the help of BOPP tape.

The reason for which BOPP tapes are used is because of their easy printability. The film material of this tape absorbs dyes very easily and after printing they do not transfer or bleed onto each other.

As this tape has age and water-resistant properties the ink does not smudge or discolouration does not take place.

Conclusion

In this article about BOPP tape, we had a deep discussion about the BOPP tape and its manufacturing as well as the benefits of using them. We have tried to break things into smaller parts so that they are easy to understand.

Hope that we were able to deliver what we promised.

Thank you for reading till the end.

Suman Mandal has been in the packaging industry for a long time. She is passionate about the innovative ways this industry comes up with. Currently, she is writing for To The Packaging about various packaging solutions.