A Comprehensive Guide To Printing Techniques On Corrugated Boxes

If you are looking for a single place where you will get all the information that you need for printing on corrugated boxes, then this blog is for you.

The corrugated box is the oldest packaging solution that was invented in the 1700s and is still in use. Not just corrugated boxes are the single most popular means of packaging that is recycled up to 94% of the total amount manufactured.

All being said they are compostable, keep our package safe and are easily customisable with different types of cuts and printing.

As we have said in the beginning, we will talk about the different types of techniques that are used to make prints on Corrugated Boxes.

Let’s start.

What Type Of Printing Is Used In Corrugated Boxes?

These days we have options and choices for printing many types of customised prints on the box. As it is important to have high-quality prints that are within your budget.

Down below, we have listed 4 types of printing techniques that are used on corrugated boxes.

Flexography Printing Technique

Flexography is a technique which is similar to the old methods of printing that were developed in the early stages of the printing press.

We can understand flexo, as a method of relief printing where the ink is applied to the raised image on a flexible (Flexo) plate. Then it is pressed onto the media.

Given its drastic improvement in the field of printing, it is used to print all kinds of flexible packaging as well as high volumes of labels.

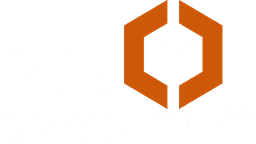

The process starts with optimizing a label for making a plastic photopolymer plate that will be treated with UV light. Then the process starts with coating the flexo sheet onto a cylinder that is called a plate cylinder.

Three cylinders are named Anilox Roll Carrier, Impression Cylinder and a plate cylinder. These three are the main cylinder used in this type of printing.

Then the Anilox Roll Carrier carries ink from the ink reservoir and then to the impression plate. That will print the colour on the paper. The colours used in this type of printing are Yellow, Cyan, Magenta and black, popularly known as CMYK.

Flexographic printing is seen to provide high-quality printing on a variety of labels and custom box printing. Flexography is considered a better option if you have top printing high volume of prints that are in different varieties as well as sizes.

Offset Lithography Technique

Offset printing is just like any other type of printing but the main difference is the use of a metal plate mostly aluminium, due to its malleability.

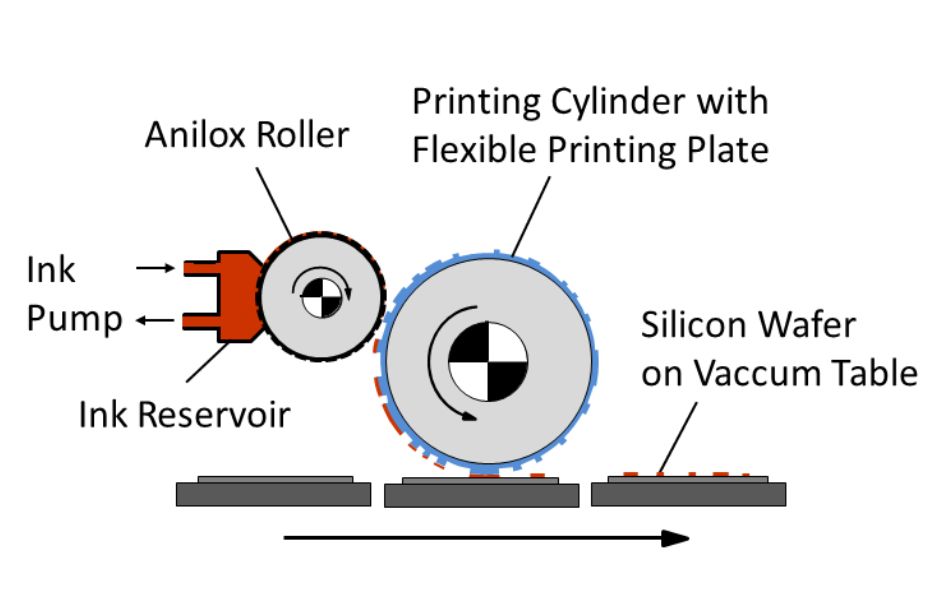

The process starts with an aluminium sheet on which a laser is used to imprint the image or the text whatever is required. Then the sheet is folded into the surface of the cylinder.

The aluminium sheet is called the Press Plate. As each printing press uses, one plate. So for different colours, we need different press plates.

The process starts with damping the cylinder on which the press plate is kept. Water and other chemicals are applied to the non-image side of the plate to create suction.

Then from the ink fountain, the press plate gets ink on its surface. Then another cylinder named blanket area prints and squeezes the excess paint out of the printing cylinder.

Then the paper comes between the impression cylinder and the blanket cylinder which is when the paper gets its required printing onto the paper.

After that, a transfer drum picks up the paper, transfers it to another drum and dries it.

Screen Printing Technique

Screen printing is one of the most popular types of printing methods, especially for customised products like T-shirts, posters, cards, metal etc.

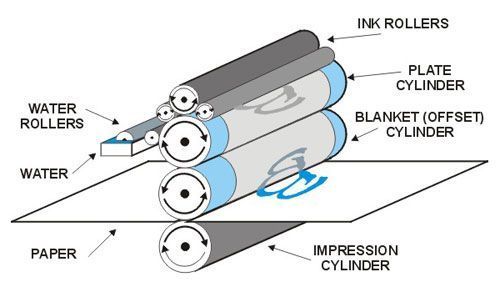

In screen printing, we have a rectangular frame which has a mesh screen inside its frame. On the mesh screen, we have a screen that has a stencil of the desired designs.

A tool named Squeegee is a scraper type of tool that is used to scrape the ink from one side to another.

The process of screen printing starts with placing the substrate under the mesh of the frame. Choose the required colour that you want to use.

Pour some colour on the frame and scrape it up and down. Now place the substrate directly under the frame. And now after that, you need to scrap the paint in the Up and down direction twice.

This leaves us with a stencil-designed print. The same process can be used with several different colours.

This is the preferred form of printing for customisation because, unlike the other forms of printing. Screen printing can use many different colours and is best for printing on different kinds of objects.

The ink used in screen printing is specially made to dry up quickly and adheres perfectly when heat treated. As we can use multiple colours to get a detailed and sharp image, which is not possible in the other forms of printing techniques, which is why it is the most preferred printing technique when it comes to customisation.

This type of printing is done on many surfaces like Fabrics, paper, wood, glass, metal, or plastic.

Digital Printing Technique

Digital printing is the emerging side of the packaging industry. Digital printing is done similarly on the other substrate just like we see normal printers working.

We can say that in this printing, a printer directly prints the digital-based images on different substrates or media. It is best for people who need to print less than 1000 prints.

It is cost-efficient as it will not require any extra plate like we need in Flexography and offset printing.

There are different types of printers that we can use in digital printing which are inkjet and laser, solid ink, Digital process and Dye.

We can use this printing method for fabrics, Linen, corrugated Boxes and thick paper cards.

What Is The Best Type Of Printing For Packaging?

Now comes this question. Which is the best type of printing for packaging? For this, we will consider two things which are quantity and quality.

In the packaging business, it is essential to estimate how many prints we need for our business. If you want the quality to be high even if the volume is low then you can use all the printing techniques that are stated above, especially digital printing.

But if you want the quantity to match the quality of the prints then you can opt for Flexography and offset printing.

That’s all we had to say about different types of printing techniques.

Thank you for reading!

Suman Mandal has been in the packaging industry for a long time. She is passionate about the innovative ways this industry comes up with. Currently, she is writing for To The Packaging about various packaging solutions.